Industry News

The **TPU cooler bag** has become the gold standard in premium outdoor cooling, primarily due to its superior durability and, most critically, its absolute water tightness. Unlike traditional soft coolers with stitched seams, the TPU construction enables hermetic sealing, ensuring ice retention and preventing catastrophic leaks, even when submerged. Achieving this reliability requires rigorous adherence to the IP rating standards for TPU cooler bag design and advanced manufacturing processes, particularly in the closure system and seam construction.

F-007 TPU Portable Soft Cooler With Adjustable Strap for Camping

The Ingress Protection (IP) rating system provides a precise, standardized measure of a product's resistance to solids and liquids. For a high-quality **TPU cooler bag**, the focus is on the second digit (X), which denotes liquid resistance.

The required IP rating varies by intended use. While an IPX6 rating is sufficient for basic camping and preventing internal liquids from escaping, a true fishing or marine-grade **TPU cooler bag** must achieve IPX7 compliance. This higher standard assures the buyer that the cooling contents remain dry and secure even during brief, full submersion, reinforcing the importance of the IP rating standards for TPU cooler bag.

| Closure Type | Water Resistance Level (Typical) | Primary Sealing Mechanism |

|---|---|---|

| Standard Sewn Zipper | Water Resistant (IPX3 - IPX4) | Fabric Flap / DWR Coating |

| Waterproof Zipper | Watertight (IPX6 - IPX7) | Sealing Ribs / Pressure-Molded Teeth |

| Roll-Top | Watertight (IPX6 - IPX8) | Compression of TPU Layers |

The choice between closure systems represents a major technical decision, directly impacting accessibility and water rating.

The roll-top closure, often used in a **TPU cooler bag**, achieves its seal by repeatedly folding the TPU fabric and securing it with buckles. In a Roll-top vs zipper waterproof cooler comparison, the roll-top is often rated to IPX8 (continuous immersion) because its seal is created by high-pressure, multi-layer compression, making it fundamentally more impervious to hydrostatic pressure than a mechanical zipper system.

The true measure of a cooler bag's durability is not its material, but the strength of its seams.

Weld strength is quantified via tensile and peel tests. During RF welding strength testing for cooler bags, engineers measure the force required to peel the fused layers apart. A successful, high-quality weld should be stronger than the surrounding **TPU cooler bag** material, meaning failure occurs in the base fabric, not the weld itself.

Reliable **TPU cooler bag** production relies on systematic verification methods to ensure zero leakage.

Seams must resist failure not only under pressure but also under repeated flexure and folding. High-end **TPU cooler bag** testing includes dynamic load and folding simulations to ensure that the RF weld remains intact and leak-free throughout the product's expected lifespan, addressing the challenges faced in Quantifying leak prevention in TPU cooler bag seams over time.

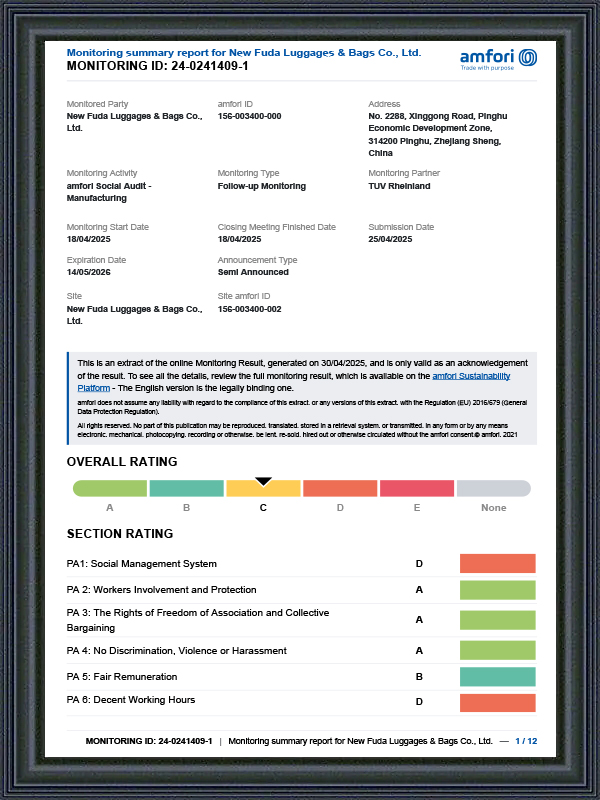

New Fuda Luggages & Bags Co., Ltd., established in 2006, specializes in the research, development, and manufacturing of outdoor sports, cycling, fishing, and travel luggage. Our production technology emphasizes both traditional sewing and advanced high-frequency (RF) welding. Our high-frequency pressing series, including our **TPU cooler bag** line, has become the preferred choice for cross-border head sellers due to excellent product quality and reliability. We export products to Europe, America, and Japan, focusing on delivering solutions that meet stringent requirements, such as the IP rating standards for TPU cooler bag designs. We have extensive experience in RF welding strength testing for cooler bags to ensure our seams are stronger than the material itself, allowing us to confidently navigate the technical demands of both the Roll-top vs zipper waterproof cooler comparison and guarantee superior performance.

IPX7 is generally the minimum standard for a high-quality TPU cooler, as it guarantees the bag can withstand temporary immersion in water (e.g., being dropped into a lake or stream) without leakage.

Standard sewing punctures the material and requires sealing tape, creating potential failure points. RF welding uses high-frequency energy to fuse the TPU at a molecular level, creating a continuous, watertight, and often stronger seam without holes.

The primary method is pressure testing, either by applying internal hydrostatic pressure (filling with water) or by inflating the bag with air and submerging it to check for bubbles, verifying the hermetic seal achieved by welding.

The roll-top closure often achieves a higher rating (up to IPX8), as the seal is formed by multiple folds and compression of the highly resilient TPU material, making it inherently resistant to sustained hydrostatic pressure.

Durability is ensured by the robust mechanical design of the zipper (pressure-molded teeth and sealing ribs) and the zipper's integration into the TPU fabric via strong RF welding, which resists the strain of repeated flexing and opening/closing cycles.

Your email address will not be published. Required fields are marked *

The waterproof zipper backpack TPU portable soft cooler maintains the dryness and coolness...

View MoreOutdoor waterproof fishing bags are multifunctional equipment bags designed for fishing en...

View MoreEmbarking on a road trip or an outdoor adventure often comes with the challenge of fitting...

View MoreIn today's fast-paced life, more and more people are keen on outdoor travel, exploring the...

View More* Your email is safe with us, we don't spam.

Professional R & D and manufacturing of outdoor sports, cycling, fishing, business, travelling sewing, high-frequency stamping series of luggage enterprises

E-mail: christine@fudabags.com

Phone: +86-13819351116

Add: No.2288 Xinggong Road, Pinghu City, Jiaxing City, Zhejiang Province, China

Copyright © 2025 by New Fuda Luggages & Bags Co., Ltd. Rights Reserved.Custom Durable Outdoor Travel Bag Manufacturers

English

English Français

Français Español

Español